Measures against Solid Noise of Transformers

- Category

-

-

- Type of equipment/device

-

- Air conditioning/Sanitary equipment

- Electrical equipment

- Buildings/Structures

- Precision equipment

- Vibration-sensitive equipment

-

- Vibration obstacle phenomena

-

- Vibration

- Noise

- Magnetic fields

-

- Type of usage environment

-

- Living environments

- Office buildings

- General facilities

- Factories

- Research facilities

-

- Building type

-

- Hotels/Accommodations

- Hospitals/Welfare facilities

- Office/Meeting rooms

- Store/Commercial buildings

- University Labs/Schools

- Condominiums/Houses

- Plants/Factories

-

- Solid noise caused by transformer energization in the treatment room directly below the electric room of the hospital

- A solid noise was generated due to the energization of the transformer in the treatment room just below the electric room of the new hospital, which was pointed out by the client inspection. As a countermeasure against this, measures were taken to replace the manufacturer's standard rubber with springs, eliminating solid noise.

Countermeasure points: A small spring anti-vibration unit is applied to improve performance while clearing dimensional restrictions.

Since the performance of vibration isolation measures using the manufacturer's standard rubber was not sufficient, it was necessary to upgrade the vibration isolation, but the standard spring vibration isolation frame did not fit in the panel, and this time a small spring vibration isolation unit ( By applying the TRV-N type), we were able to satisfy the target environment while keeping it inside the panel.

Cause: Anti-vibration grade selection error

Although the original design specified spring anti-vibration for this transformer, because the vibration and noise target values were not set directly below the electrical room (the room immediately below was the treatment room, etc., the hospital room was directly below the adjacent span). According to the sole judgment of the trader, the standard rubber of the manufacturer was used for vibration isolation. At the self-inspection stage by the general contractor before delivery, the effect of the transformer was not noticeable because the load was small, but the increase in load after delivery increased the noise directly under the transformer and was pointed out in the client inspection. The noise environment directly under the measures (at the time pointed out) reached NC-50 at the maximum, and the noise level was not negligible. As a result of the investigation, it was determined that the performance of the manufacturer's standard anti-vibration rubber was insufficient, and we decided to take measures to replace the anti-vibration rubber with a spring.

-

Whole transformer in the panel (before measures)

-

Manufacturer's standard rubber mounted on the transformer leg

Countermeasure: Countermeasure using spring vibration isolation unit (TRV-N type)

It was decided to replace it with spring anti-vibration, but there was a dimensional limitation (in the existing board). Regarding the vibration isolation measures, it was thought that a standard anti-vibration stand was desirable from the viewpoint of earthquake resistance and suppression of sprung displacement, but it was found that the anti-vibration stand does not fit in the panel in the height direction. It was decided to use a spring anti-vibration unit (TRV-N type) that can obtain the same anti-vibration effect, although an additional effect cannot be expected.

-

Whole transformer in the panel (after measures)

-

TRV type vibration isolation unit mounted on the transformer leg

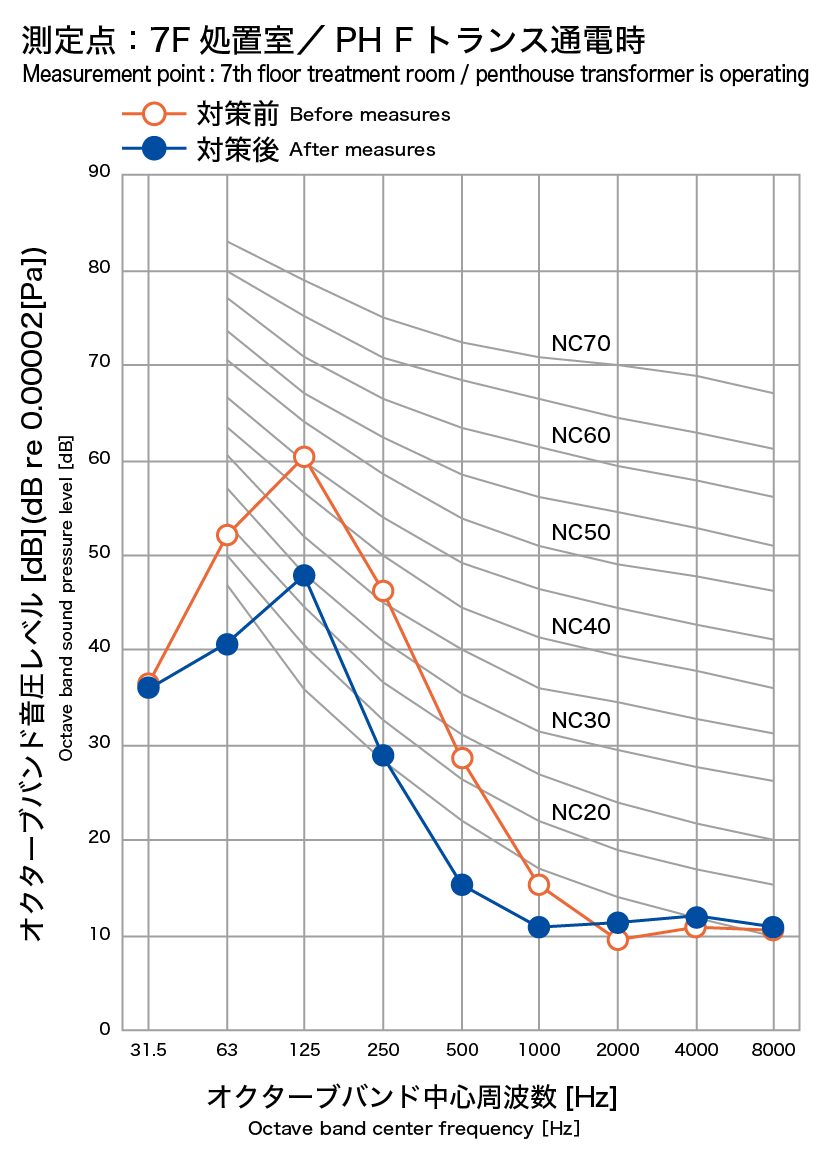

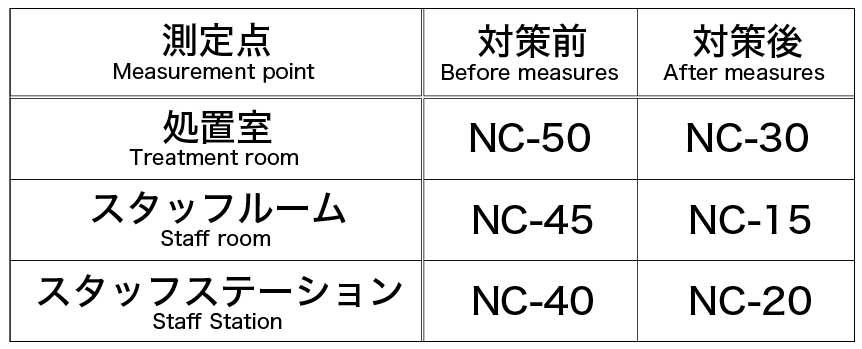

Effect: Noise level is reduced to NC-30 or less and obstacles are eliminated

As a result of this measure, the noise level directly below was reduced to NC-30 at the maximum. The owner who was pointed out was satisfied with the great reduction effect, and the noise obstacle was resolved.

-

Comparison of treatment room noise before and after countermeasures

-

Noise comparison of each room directly below the floor before and after countermeasures