Example of Noise Measures by Vibration Insulation of Large-Diameter Vertical Piping

- Category

-

-

- Type of equipment/device

-

- Air conditioning/Sanitary equipment

- Electrical equipment

- Buildings/Structures

- Precision equipment

- Vibration-sensitive equipment

-

- Vibration obstacle phenomena

-

- Vibration

- Noise

- Magnetic fields

-

- Type of usage environment

-

- Living environments

- Office buildings

- General facilities

- Factories

- Research facilities

-

- Building type

-

- Hotels/Accommodations

- Hospitals/Welfare facilities

- Office/Meeting rooms

- Store/Commercial buildings

- University Labs/Schools

- Condominiums/Houses

- Plants/Factories

-

- Measures against solid noise near the vertical piping shaft for cooling water

- Solid noise was generated in the vicinity of the vertical pipe shaft for cooling water of 750A, but by replacing the existing steady rest with a steady rest that has a high vibration isolation effect, the noise level from NC-45 to 55 was NC- It was greatly reduced to 25 to 30 and the noise obstacle was resolved.

Countermeasure points

By adopting a non-contact type steady rest, a large vibration reduction effect is obtained.

Cause: Solid sound disturbance caused by the vibration propagating from the steady rest to the body

Noise was generated in the vicinity of the steady rest of the 750A vertical pipe for cooling water, and as a result of investigation, it was found to be a solid sound disturbance due to the vibration propagated from the steady rest to the body. As shown in Fig. 1, the existing steady rest is a type in which a rubber pad is sandwiched and tightened with steel plates, and the pipe and steel frame contacted to transmit vibration.

-

Figure 1: Existing steady rest where pipe vibration propagated

-

Figure 2: New steady rest with high vibration isolation

Countermeasure: Change the vibration isolation method of steady rest to non-contact type

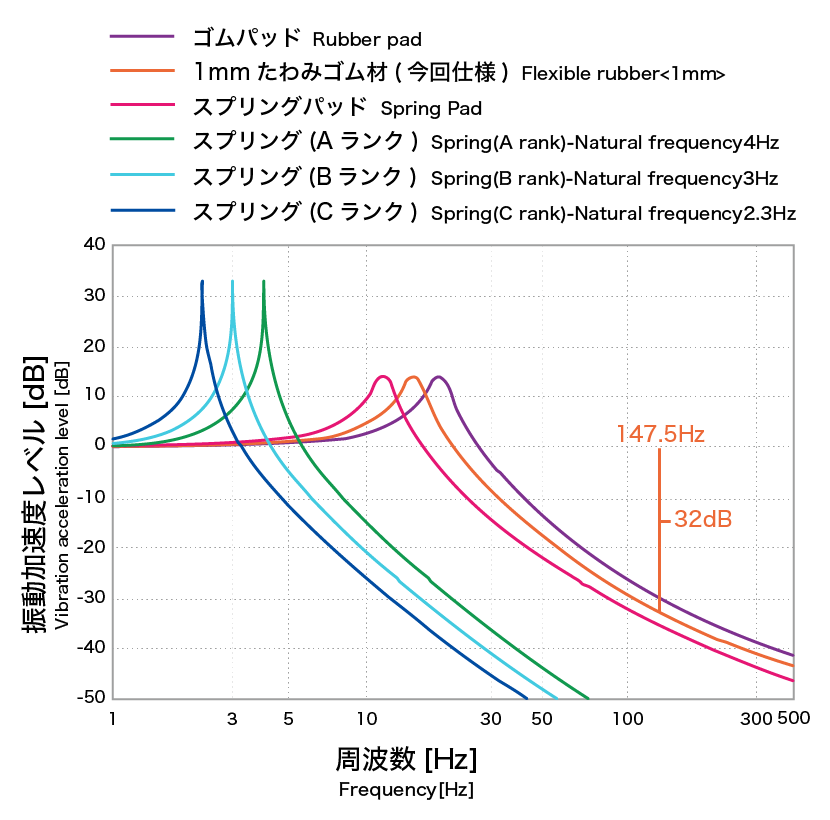

We have newly delivered a non-contact type steady rest. Unlike the conventional steady rest, the clearance with the pipe is increased to prevent the vibration of the pipe from propagating to the body. A 6-point rubber is placed inward as a piping guide to serve as a cushioning material when the piping comes into contact (Fig. 2). The amount of rubber deflection during contact is assumed to be approximately 1 mm, which is effective in suppressing excessive pipe displacement. The vibration isolation level is positioned as an intermediate performance between the rubber pad and the spring pad as shown by the orange line in Fig. 3.

-

Figure 3: Comparison of vibration isolation levels for each vibration isolation material

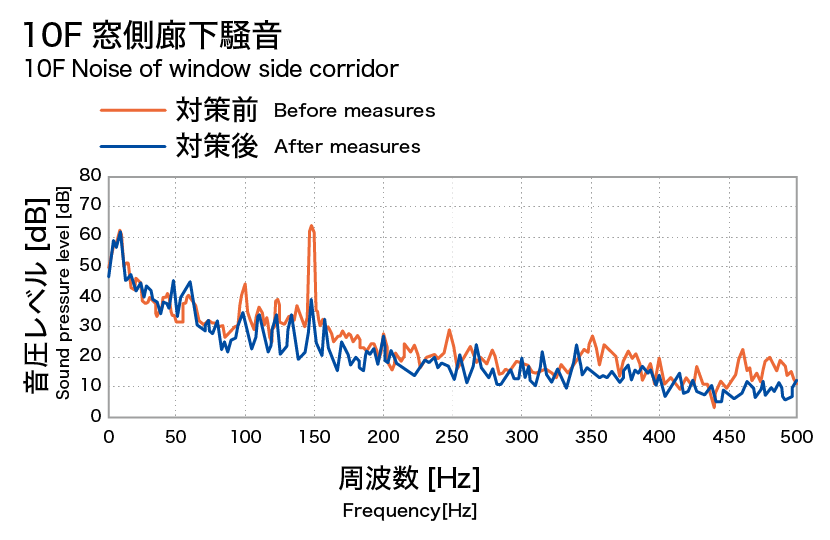

Effect: The main noise component, which was a problem, is reduced to less than 1/10

The main component of the vibration propagating from the pipe is the peak component of 147.5Hz (4 pole motor 24.5Hz x pulsation of 6 blades) as shown in Fig. 4, and this component is 20dB or more (1/10 or less) due to steady rest update measures. To). The noise level near the shaft on each floor was NC-45 to 55 before the countermeasure, but was reduced to NC-25 to 30 after the countermeasure.

-

Figure 4: Comparison of sound pressure spectrum near the shaft before and after countermeasures

-

Figure 5: Noise measurement near the shaft